Commercial Thrusters from Side-Power

Commercial vessels often require larger more powerful thruster systems, or those capable of performing in specific working conditions.

AMI recommend Side-Power's AC or Hydraulic Thrusters, designed fit to purpose for commercial marine and available in a variety of options to suit the existing onboard systems.

Side-Power AC Thruster Systems

AC Thrusters are delivered complete with all main components for easy Plug & Play installation: Gear leg and prop, saddle, flexible coupling, AC motor, Variable Frequency Drive, control box, S-link™ cabling and proportional Joystick control.

All Side-Power AC models use the S-link™ CAN-based control system with full intelligent communication between all units in the system, much like a computer network.

Low Harmonic VFD's

A system with a standard VFD will create a certain level of distortion to the AC network. The actual THD in a system will vary depending on other loads, available generator capacity, total generator capacity etc.

In addition to the standard VFD's, we can deliver low harmonic VFD's for installations with specific THD requirements. Side-Power system with a low harmonic VFD will reduce the harmonic distortion to less than 5% which gives the following advantages:

- Keep the electrical network clean

- Reduce the risk of disturbance

- Prevent damage to other equipment

- Prevent interference with communications equipment

- Reduced need for oversizing of the generators

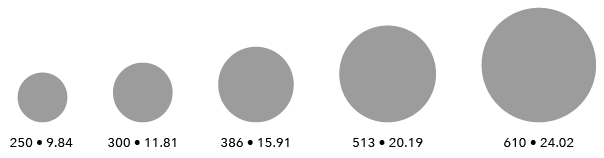

Available tunnel sizes:

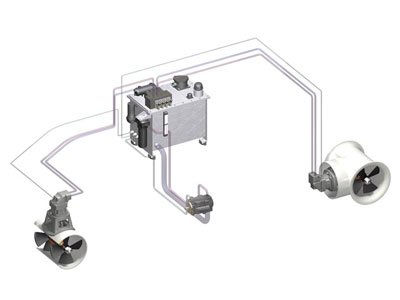

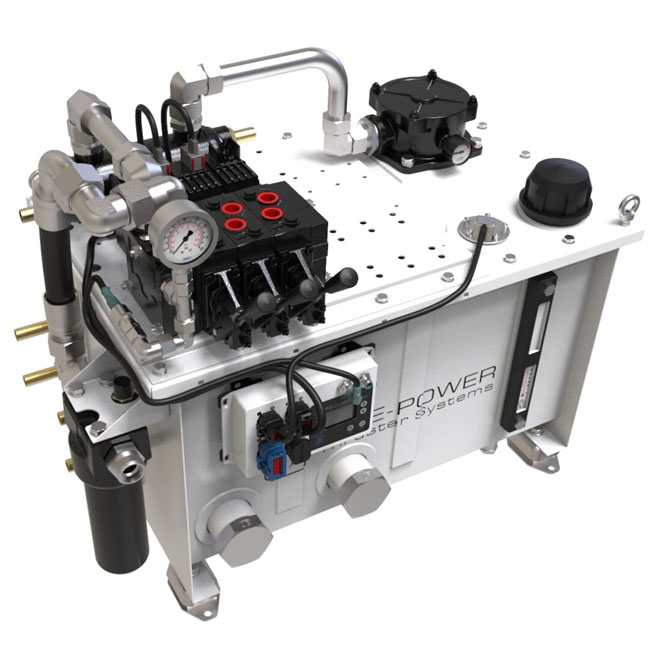

Side-Power Hydraulic Thruster Systems

A hydraulic thruster system is the natural choice when extensive thruster usage or long run cycles are required. Side-Power design their hydraulic systems with the style needed for pleasure craft and the reliability necessary for commercial use.

For many vessels, a hydraulic system makes sound economic sense since several functions can run off one central hydraulic source. Once the basic system is in place (pump, reservoir, cooler), adding a function is simply a matter of adding a relatively inexpensive hydraulic valve. This approach is more efficient and cost effective than running each individual function with its own electric motor, solenoid, fuse and battery switch, especially with larger equipment. Additionally, hydraulic valves and motors are better choices in harsh environments such as the forepeak, bilge and transom areas, as well as areas requiring ignition protection. Typical hydraulic applications are thrusters, stabilizers, winches, capstans, cranes, etc.

There are many different ways of designing hydraulic systems, and some solutions are better for specific applications than others. Side-Power Hydraulic systems are designed to provide outstanding performance of the core components and flexibility to power multiple additional equipment.

A Side-Power Hydraulic System Is specifically designed for ultimate flexibility to support any of the other hydraulic parts on board.

It has been designed using the same stringent standards as all other Side-Power parts, focusing on:

- Reliability

- Safety

- Easy & safe installation

- Straightforward maintenance